Everything about Polyester Staple Fiber

15 month 05 2024

Share

Polyester fibre is the most widely used chemical fiber and has the most significant volume consumption compared to other fibers like acrylic, nylons, rayon. The fiber is produced at lower prices due to petrochemical resources. The salient features like strength, easily dye-able, wrinkle-resistance, and lightweight make them a great alternative across different industries. Polyester staple fiber is alterable according to specific industry needs, and hence, it is a preferred choice.

What is Polyester Staple fiber?

Chemically, polyester is a monomer containing the ester functional class. PSF is made by continuous polymerization involving purified Terephthalic acid (PTA) and mono ethylene glycol (MEG). Catalysts are used in the process that controls the reaction process. Here are some significant properties of polyester fiber:

- Melting point: 260-270 °C

- High rot resistance

- Excellent acid resistance

- Great weathering resistance

- Resistant against organic chemicals

- High strength

- Wrinkle and shrink-free fiber

- Quick-drying

- Retains creases and pleats set using heat

- A dye-able fabric makes them a popular choice.

Application about Polyester Fiber

Considering the properties of the fiber, manufacturers prefer using it in their products. Below are some significant uses of the fiber:

- Clothing and fashion industry: Sportswear, dresses, lining, shirts, suits, neckties, undergarments, and more.

- Furnishing: Pillow and cushion covers, curtains, bedsheets, carpets.

- Textile: Nets, floor covering, ropes, etc.

- Automobile: Seat filling and covers, mats, speaker felts.

- Plush toy

- Other application: Filter tanks, insulation panels, clocks, etc.

There are two broad types of polyester fiber: virgin and recycled. While virgin polyester involves the MEG and PTA polymerization, Recycled polyester staple fiber (RPSF) is obtained from plastic waste and re-spinning into new, reusable fibers. Recently, RPSF has gained popularity since governments promote plastic waste recycling. This is done through policies like EPR, where plastic manufacturers are expected to take back and recycle plastic that they introduce into the environment. RPSF is manufactured using plastic bottles, waste containers, etc.

Consumers are becoming aware of the facts associated with recycled polyester fiber and are now demanding products made of the material. RPSF has all the properties that a virgin polyester fiber has; however, it consumes much lesser resources in production. This sustainable practice needs to continue in the coming years to help divert waste from junkyards and transform them into valuable products.

Recycled polyester staple fiber has bought a much-needed revolution to facilitate better plastic waste management. Polyester, be it virgin or recycled, has applications in almost every industry. This is why manufacturers of these fibers ensure that they produce good quality fiber to meet customers' needs. The clothing industry is undoubtedly the biggest consumer of polyester. With the introduction of RPSF, brands are making clothes of high quality and offering them at reasonable prices to the customers. This new trend will contribute to a cleaner environment essential to maintaining the environmental balance.

Related news

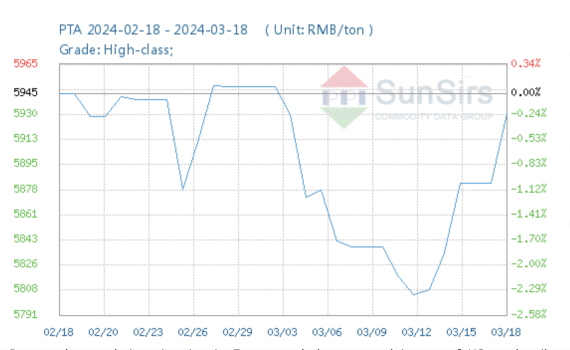

SunSirs’ analysts believe that in the short term, cost-side PX maintenance expectations and PTA maintenance expectations will boost the cost side. The number of new orders issued by the terminal textile and clothing industry may gradually improve, and after the domestic and foreign markets gradually improve, the intention of downstream replenishment on demand will also further increase. There is an expectation of improvement in the fundamentals, and it is expected that the price of polyester staple fiber will fluctuate and rise slightly.

15 month 11 2023

Do you need advice

We are always ready to discuss and listen to your requests and contributions. Please leave your information and Vu Gia will contact you as soon as possible

Search

Search